Designing a modern engine means meeting three demands at the same time. Drivers want quick response and strong pull when they accelerate. Owners and fleets want lower fuel use in everyday driving. Regulators require very low tailpipe emissions across a wide range of temperatures, speeds, and loads. These goals are connected, so improving one can make another harder.

More power typically means burning more fuel, while the cleanest emissions outcomes often require specific combustion conditions that are not always the most efficient or the most powerful. Good engine design is the art of selecting hardware and control strategies that deliver the needed performance while keeping fuel consumption and pollutants under tight control.

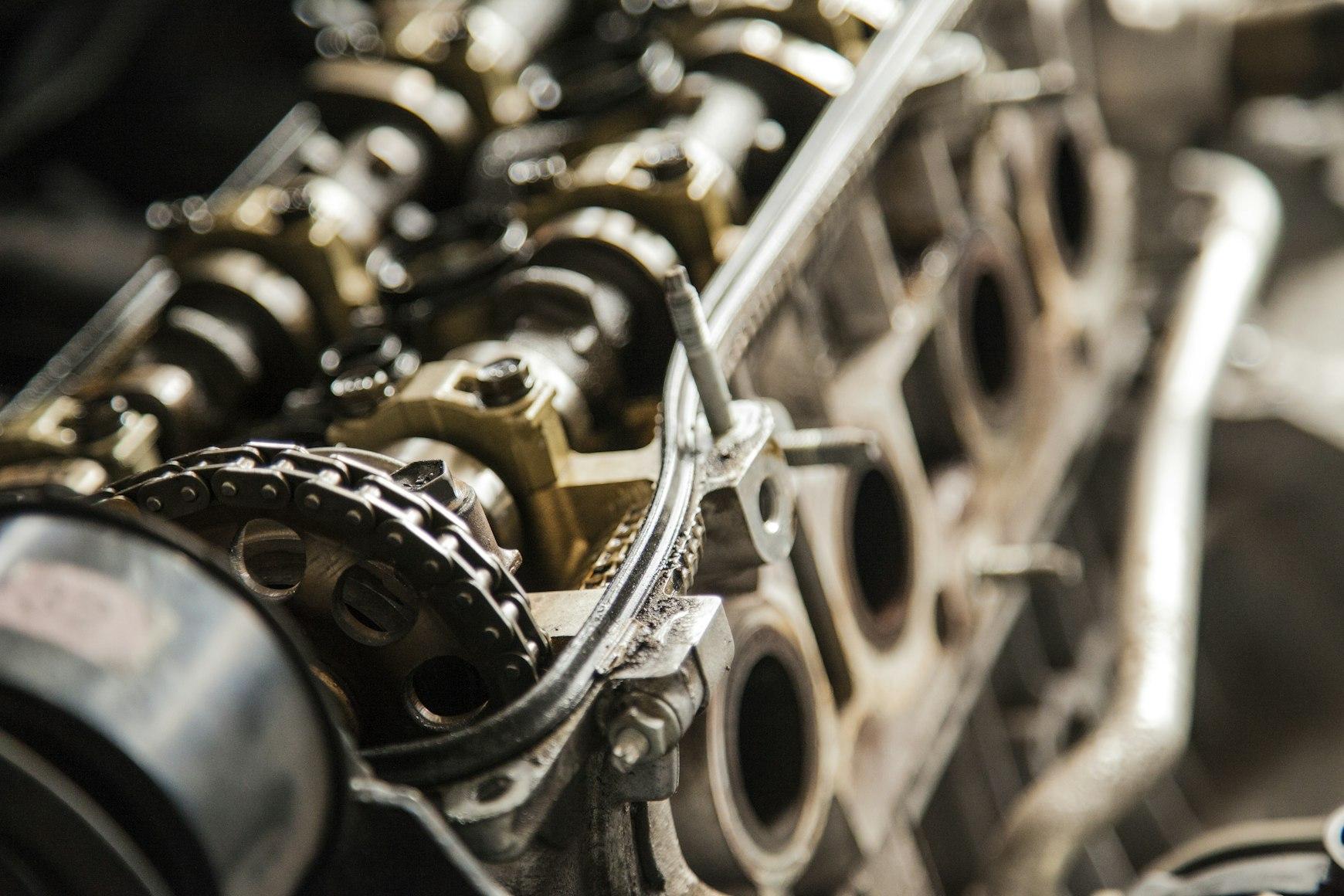

Combustion efficiency is the foundation

Most of the balancing act starts inside the cylinder. Power rises when the engine can fill the cylinder with air effectively, mix fuel evenly, and burn that mixture quickly and predictably. Fuel economy improves when a greater share of the fuel’s energy becomes useful work instead of heat lost to the exhaust or cooling system. Emissions improve when combustion is stable and complete, because incomplete burning increases hydrocarbons and carbon monoxide.

Combustion chamber shape, piston crown design, and intake port geometry all influence air motion. Carefully managed swirl and tumble can speed up flame travel and reduce cycle to cycle variation. That stability matters because unstable combustion forces conservative calibrations that waste fuel and can increase emissions. Compression ratio is another lever. Higher compression generally improves thermal efficiency, but it increases knock risk. Designers counter that with better cooling, optimized chamber geometry, precise spark control, and, in many cases, controlled dilution using exhaust gas recirculation to reduce peak temperatures.

Displacement choices and boosting strategy

Engine size strongly influences how easy it is to make torque. Larger displacement can produce strong low speed torque with less reliance on high engine speed. That can feel effortless and can reduce the need for frequent downshifts. The drawback is that a larger engine may carry higher friction and may spend much of its life operating at light load where efficiency is lower.

Downsizing paired with turbocharging is a common alternative. A smaller engine can run at higher, more efficient loads during typical driving, then use boost when the driver asks for more power. Boosting, however, raises cylinder pressures and temperatures, which increases knock risk and can influence pollutant formation. Managing charge air temperature with intercooling, selecting an appropriately sized turbo, and using precise control of fuel and spark are essential to keep both efficiency and emissions on target, especially during rapid accelerations. Real world power expectations also shape design choices in widely used configurations such as the 5.3 chevy engine, where calibration and airflow management play a central role in delivering usable torque while meeting modern standards.

Airflow and valve control across the driving cycle

An engine rarely operates at wide open throttle in normal driving. Much of the time it runs at low or moderate load, where pumping losses can be a major efficiency penalty. Variable valve timing helps by changing when the valves open and close to suit the situation. At light load, valve timing strategies can reduce throttling losses by controlling air more through valve events than through a mostly closed throttle plate. At higher load, valve timing can be optimized for airflow and cylinder filling to support power.

Some engines go further with variable valve lift or advanced cam phasing strategies that allow greater flexibility. The benefit is that the same engine can act efficient and restrained in cruising, then shift to a higher breathing mode under acceleration. That adaptability is one of the biggest reasons modern engines can offer both strong performance and better fuel economy than older designs with fixed valve events.

Fuel delivery and mixture preparation

Fuel system design has become one of the most important determinants of the power economy emissions balance. Direct injection can improve efficiency and power by cooling the intake charge and enabling very precise fueling. It can also reduce knock tendency, which supports higher compression or more boost. At the same time, direct injection can increase particulate emissions if fuel spray contacts surfaces or if mixing is poor during transients. That is why injector placement, spray pattern, injection pressure, and injection timing are critical. Some designs combine port and direct injection to reduce particulates in certain operating regions and to keep combustion and deposits more manageable over the long term.

Reducing losses with friction and thermal management

Not all efficiency gains come from combustion. Reducing friction improves fuel economy without sacrificing power. Low tension rings, improved bearing and coating technologies, optimized oil pump control, and refined valvetrain components can each shave off small losses that add up.

Thermal management also matters for both economy and emissions. Engines are least clean and least efficient when cold. Faster warm up reduces cold start pollutants, and keeping temperatures in an optimal range improves efficiency and consistency. Modern cooling systems often use smart control of coolant flow and thermostat behavior to speed warm up and maintain stable operating temperatures under varying loads.

Aftertreatment and calibration as the final gatekeeper

Even perfect in cylinder combustion cannot eliminate all pollutants. Catalysts and filters are designed to convert or trap the remaining emissions. For gasoline engines, three way catalysts work best when the engine operates near stoichiometric conditions, so calibration often prioritizes maintaining that window as much as possible. Increasingly, particulate filters are used to control soot from direct injection systems. Sensors and onboard diagnostics ensure the system stays effective over time, and control software continuously adjusts fuel, spark, airflow, and sometimes dilution to protect the aftertreatment while minimizing fuel penalties.

Conclusion

Balancing power, fuel economy, and emissions is not a single trick. It is the result of coordinated decisions in airflow design, combustion chamber engineering, valve control, fuel system technology, friction reduction, thermal management, and exhaust aftertreatment. The best engines are built as integrated systems where hardware and calibration are developed together, allowing strong performance when needed, efficient operation in everyday driving, and consistently low emissions in real conditions.